Spray booth maintenance

Spray paint operation hazards include those created by carrier solvents’ flammable vapors and the residue buildup from paint overspray. Infrequent cleaning and casual maintenance can destroy even the best designed and constructed equipment's effectiveness. Fire statistics regularly include infrequent cleaning or poor maintenance as either a cause of the loss or a factor contributing to the size of the loss. These maintenance tips are essential for the continued safe operation of a paint spray booth.1

Frequent cleaning

All booth surfaces should be kept as free from overspray deposits and residues as practical. Surfaces should be cleaned daily if necessary. Automatic sprinkler heads or other fire protection devices should be given special attention, and exhaust duct interiors and fan blades should not be overlooked. Using special or “strippable” coatings on interior booth walls will simplify cleaning.

Keep filters clean

Disposable filters should be changed frequently. Filter gauges should be used to determine filter condition and to indicate change intervals. Gauges should shut off the paint spray gun’s supply if there is not enough air flowing through the filters.

Use non-sparking tools

Scrapers and all other tools and devices used for cleaning should be made of non-sparking materials.

Cleaning solvents

Only solvents with flashpoints over 100°F should be used for cleaning purposes. The ventilation system should continue to operate during solvent cleaning. No more than one day’s supply of solvents should be kept near the booth.

Residue disposal

Scrapings and sweepings should never be left in piles on the floor or in uncovered containers. They should be wet down with water and removed from the building once the cleaning operations are completed.

Safety containers

Approved metal waste containers should be provided wherever rags or waste are saturated with finishing material. The contents of these containers should be removed from the building at the end of each work shift or at least daily. All solvents should be stored in listed or approved safety cans.

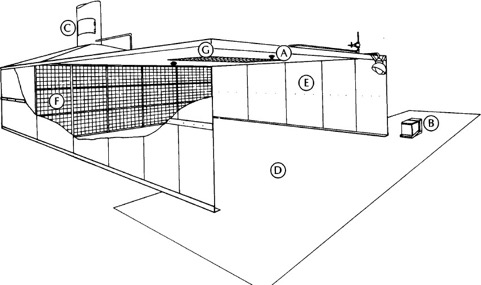

- Sprinkler heads exposed to overspray should be protected by thin polyethylene, cellophane or paper bags.

- Approved metal waste cans for used rags and waste

- Access door facilitates cleaning ductwork. Should be fitted with gaskets to create an airtight seal. Smooth, non-combustible floor or floor covering

- Smooth interior walls of non-combustible construction

- Removable filters—Change filters before airflow is severely reduced.

- Lighting fixtures—Check for paint accumulation.

Combining hazardous materials

Because some combinations of materials can ignite spontaneously, different types of coating materials should not be sprayed interchangeably. All residue should be removed from the spray booth and all ductwork before another coating material is used.

Safe distances

Maintain at least a three-foot clear space around all spray booths. This is done for maintenance purposes and to reduce the chance of fire spreading either into the spray booth or away from it. Combustible materials should not be stored near paint spraying operations.

Smoking restrictions

“No smoking” signs in large letters should be conspicuously posted near both the paint spraying operation, and paint and solvent storage areas.

Important note:

All written and diagrammatic information contained in this data sheet is believed to be accurate and has been developed from sources which The Hanover believes to be reliable. Please note, however, that The Hanover makes no representations as to the correctness or completeness of this material and accepts no legal responsibility for anything contained herein. We strongly advise that prior to undertaking any of these activities you procure a copy of the appropriate portion(s) of the National Fire Protection Association code or standard covering this subject matter and that you consult appropriate local authorities, as well as your fire insurance rating organization.

1Data Source: NFPA Standard No. 33, Spray Application Using Flammable and Combustible Materials.

To learn more about Hanover Risk Solutions, visit hanoverrisksolutions.com

The recommendation(s), advice and contents of this material are provided for informational purposes only and do not purport to address every possible legal obligation, hazard, code violation, loss potential or exception to good practice. The Hanover Insurance Company and its affiliates and subsidiaries ("The Hanover") specifically disclaim any warranty or representation that acceptance of any recommendations or advice contained herein will make any premises, property or operation safe or in compliance with any law or regulation. Under no circumstances should this material or your acceptance of any recommendations or advice contained herein be construed as establishing the existence or availability of any insurance coverage with The Hanover. By providing this information to you, The Hanover does not assume (and specifically disclaims) any duty, undertaking or responsibility to you. The decision to accept or implement any recommendation(s) or advice contained in this material must be made by you.

LC DEC 2018-506

171-0662 (10/17)